QE Innovations is proud to distribute Krummenauer shearer drums in Australia. With also our own in-house design and build facilities, mines can be assured of the right drum for the right application. Cylindrical, Globoid, Radial and Point Attack systems are available.

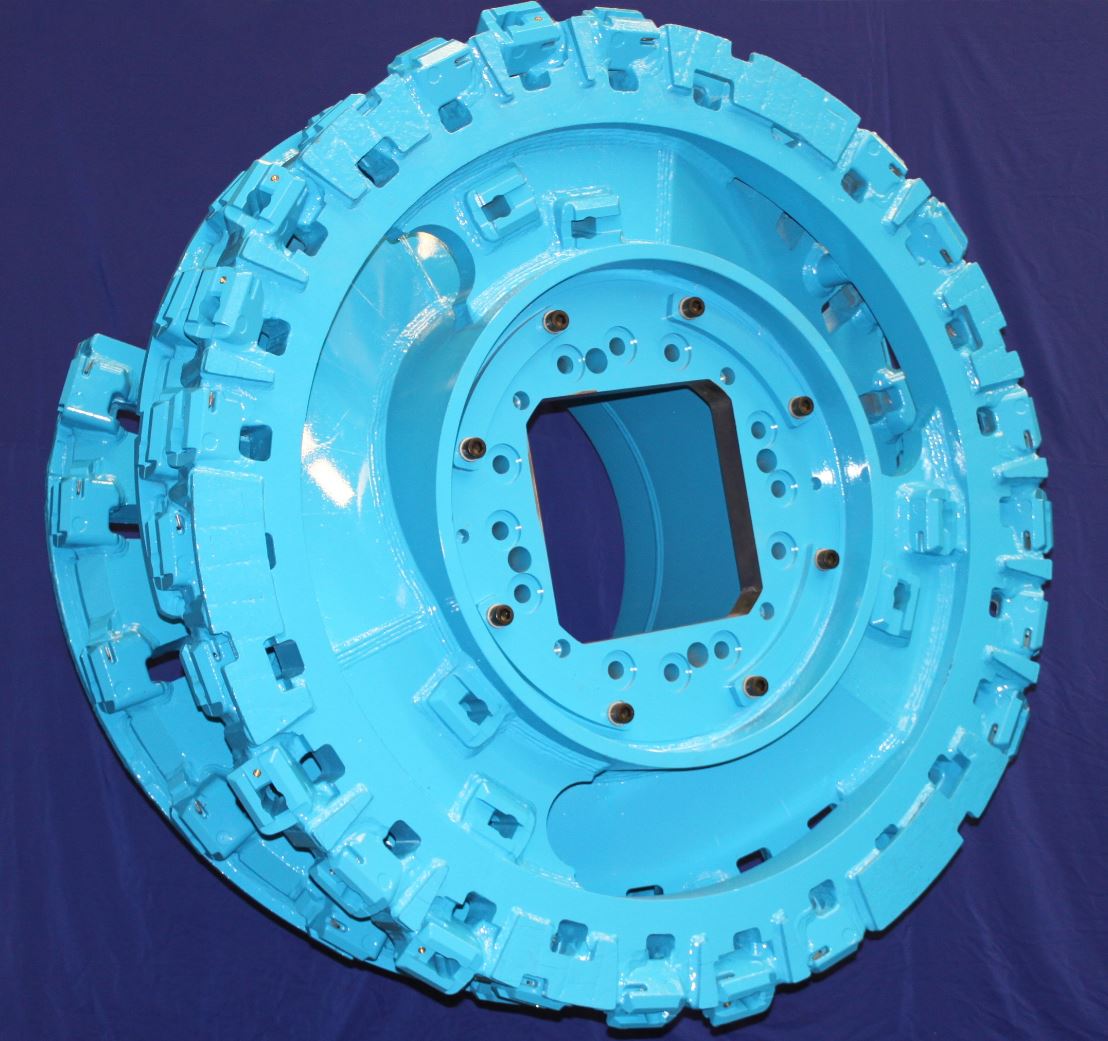

The Globoid drum in combination with the EB-water spray system sets new standards in efficiency, durability, safety and dust reduction and is exclusively available to customers of Krummenauer/QE. The output and the haulage speed are mainly limited by the loading ability of the shearer drum, provided that there is enough machine power. To increase the output Krummenauer developed the patented Globoid shearer drum. Computer calculated cutting tracks are fitted to the individual needs taking mineral and shearer loader specifications into account. The loading behavior is adjusted directly to the volume needed. This decreases coal crushing as a result of wild tumbling and thereby reduces dust formation and machine power consumption.

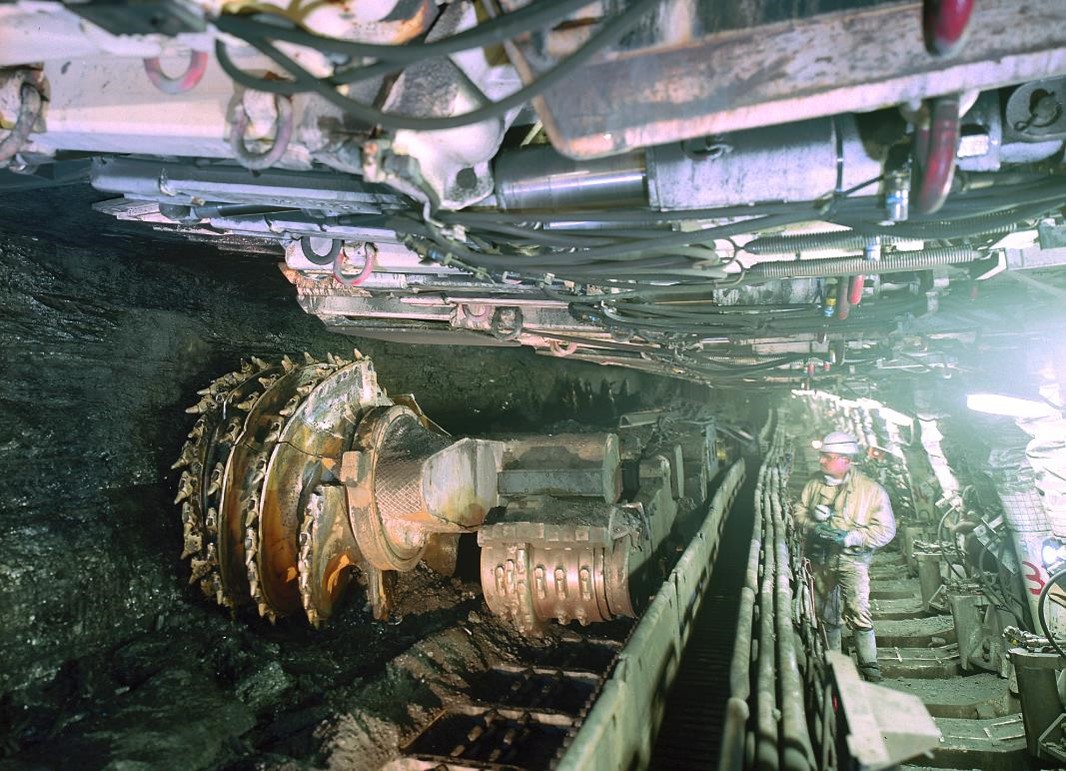

Technically qualified with market leading equipment the QE Innovations team is at the forefront of longwall shearer drum design, repair and manufacture in Australia. The shearer drum division are experienced and technically competent professionals who have spent extensive time in the field understanding the environment in which the equipment works and are committed to providing the correct drum to suit the conditions.

Lead by Lincoln Kuiper, the team has been responsible for the design, repair and manufacture of shearer drums for over a decade. Understanding the increased requirements for shearer drums in the market has lead Lincoln and his team to provide a number of innovations. In partnership with the coal mines the team has achieved:

- Supplying drums to cut 6.4 Million tonne

- Design improvements to cater for high power ranging arms

- Complete CAD design of new drums based on forecast equipment and geological conditions to achieve excellent clean up, reduced dust and high output

- Longest life between overhauls in the Australian market.

- Newly patented block system

All tradesmen working on shearer drums are certified to the correct level to allow them to weld the dissimilar metals together and provide the required pressure rating of the drum. Drums are manufactured and repaired using strict specialised in house procedures and tested on completion for tool alignment, weld and water integrity. The benefits of these procedures include better toolholder retention, improved water integrity, removal of cracking and longer life.

To discuss shearer drums please contact l.kuiper@qein.com.au